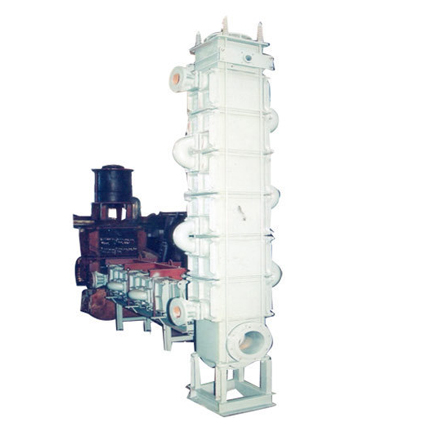

Graphite Heat Exchanger

Heat exchanger series is the most advanced design of

polyblock heat exchangers. These are constructed from identically formed

impervious graphite blocks with two types of passages viz short radial

passages of 100 to 150mm length converging into a central cavity and short

length axial passages with remixing of all the axial tube fluids in a mixing

cum redistribution channel every 150 to 300 mm travel of the axial fluid.

This particular feature of hydraulic design gives abundant turbulence even

at low flow rates and enhances the 'u' and reduces the fouling & scaling

drastically. The effect of high 'u' and lower fouling coefficient 's' is

that for the same heat duty the hta value is lower. Due to their main

features of robustness, high mechanical strength and exceptionally long

working life, these heat exchangers are widely used in pharmaceutical

industries, pesticide and fumigant sectors, dye stuffs, other chemical

process industries, petrochemicals, phosphate fertilisers and pickling lines

of steel rolling mills etc.